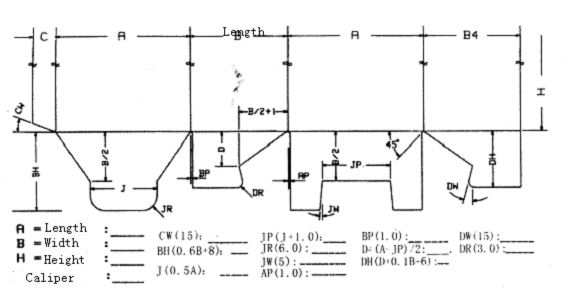

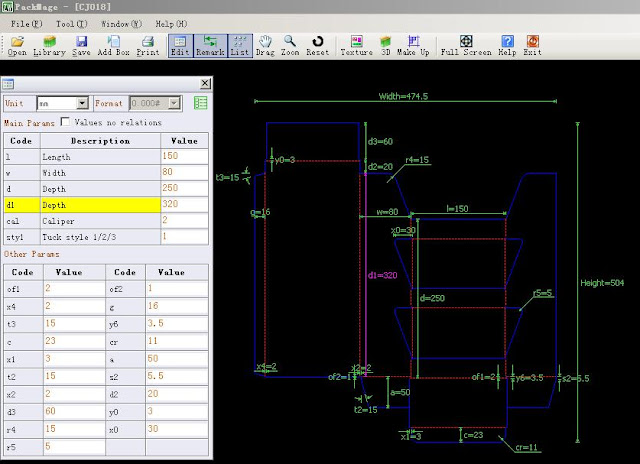

Users with CAD or manual drawing out a semi-automatic end lock structure, like the below end lock structure, you should first have a very clear mind of relationships of the sizes of the bottom main parts details.

The bottom sizes have close relationships of the main dimensions of the box, and the sizes of the length and width of box and the relationships influence the bottom structure.

Length as L, width as W and thickness of the paper is CAL. (the structure described here is L/4 > = W / 3, if L / 4 < W / 3, this structure does not not recommend, on the one hand the paper utilization rate is not high, on the other hand is a load at the bottom is not good enough.)

The first part, the relationship between the L,W dimensions and the main bottom sizes:

Y1 = W / 2,

Y2 = Y1 – CAL / 2 ( As long as Y2 is close to Y1 or smaller than Y1, depending on the paper type)

X1 = (W – CAL) / 2

X2 = (L – X1 * 2)

The X3 = X2 + CAL

Y3 = W / 4 (roughly equal to the value, can be a little smaller than it, had better not exceed W / 4)

The rest is each corner fillet, will be no more description here.

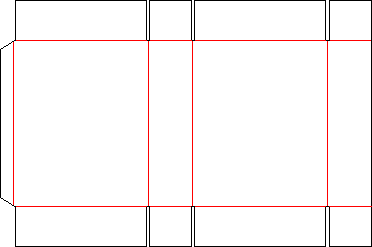

The second part,the various deformations:

The first:

Bottom of the left is enhanced, very strong, the following is a deviation angle: T1 = 30 (c).

The second:

For oblique incision on the left, the right for straight incision, T2 = 5 is an offset angle, the difference is not big. But the left side molding is more convenient.

The third:

Left for bevel, right for right-angle, T3 = 30 is a deviation angle, if coupled with the first enhanced one on the left side of the end-lock structure, the bottom of the box will buckle more tightly. But the buckle will be a little trouble.

Fourth: position change

In terms of a single box type structure, this change basically means nothing, but sometimes in order to meet the demands of layout, in order to improve the utilization rate of the paper, will be carried out in this end-lock structure. Then step and repeat.

This paper utilization rate is increased obviously in this end lock structure.

Finally, when the L value is too large, and the goods in the box is rather heavy (common fruit box), we can make the structure become polygonal to bear more load. This kind of end -lock structure is relatively complex, will be analyzed separately in a later article .